Does Stainless Steel Contain Nickel or Cobalt?

Table of Contents

- Introduction

- What is Stainless Steel?

- Does Stainless Steel Contain Nickel?

- What Role Does Nickel Play in Stainless Steel?

- Does Stainless Steel Contain Cobalt?

- Why Does It Matter if Stainless Steel Contains Nickel or Cobalt?

- Common Stainless Steel Issues: How to Handle Them

- How to Drill Through Stainless Steel

- Can Stainless Steel Rust or Discolor?

- Conclusion

Introduction

When it comes to stainless steel, you might have heard about its amazing durability, rust resistance, and strength. But, have you ever wondered what's actually inside this versatile metal? Does stainless steel contain nickel or cobalt? The truth is, stainless steel is made up of a mix of metals, and it often contains both nickel and, in some cases, cobalt. Let’s break it down in simple terms and see how these elements play a role in the properties of stainless steel.

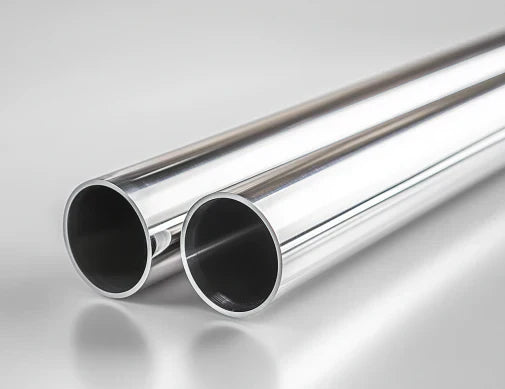

What is Stainless Steel?

Before diving into whether stainless steel contains nickel or cobalt, let’s quickly understand what stainless steel actually is. Stainless steel is a type of metal that’s made by combining iron with other metals, including chromium. The key ingredient in making it "stainless" is chromium, which helps protect the steel from rust and corrosion. But to make it even stronger and more durable, stainless steel often includes other metals like nickel, cobalt, and sometimes manganese.

Does Stainless Steel Contain Nickel?

Yes, many types of stainless steel do contain nickel. In fact, nickel is one of the most common elements used to make stainless steel. It helps improve the metal’s ability to resist corrosion, especially in harsh environments like marine settings or areas with high humidity. Stainless steel alloys with higher levels of nickel are known for their excellent resistance to rust and staining.

There are different types of stainless steel, and the amount of nickel used depends on the grade. For example, Type 304 stainless steel, which is one of the most popular grades, contains around 8-10% nickel. This gives it its famous resistance to corrosion and rust. So, if you’re using stainless steel in your kitchen or for some outdoor equipment, it’s likely that it has a good amount of nickel in it to make sure it lasts longer.

What Role Does Nickel Play in Stainless Steel?

The presence of nickel in stainless steel does more than just make it resistant to rust. It also helps improve the metal's overall strength, toughness, and workability. If you’ve ever had to work with stainless steel, you know it’s not the easiest material to drill or cut through. The nickel content in certain stainless steel alloys makes them more durable and able to handle higher temperatures without losing their shape.

Moreover, nickel also gives stainless steel a shiny, polished look, which is one of the reasons stainless steel is so popular in everything from kitchen appliances to jewelry. The more nickel that’s used in the alloy, the shinier and more durable the material becomes.

Does Stainless Steel Contain Cobalt?

Now, what about cobalt? While nickel is a common ingredient in stainless steel, cobalt is not always present. In fact, cobalt is used less frequently in the production of stainless steel compared to nickel. However, certain special stainless steel alloys, particularly those that are designed for high-strength applications, may include small amounts of cobalt.

For example, cobalt is often found in stainless steel alloys used for medical instruments or machinery that will be exposed to very high temperatures or extreme conditions. Cobalt helps to enhance the heat resistance of the steel, making it suitable for tough, high-performance tasks. If you’re working with stainless steel in a setting where temperatures or wear and tear are a concern, it’s possible that cobalt is part of the mix to make the metal more resistant to these factors.

Why Does It Matter if Stainless Steel Contains Nickel or Cobalt?

Now, you might be wondering, "Why does it matter if nickel or cobalt is in stainless steel?" Well, the answer lies in how these elements affect the overall properties of the steel.

- Nickel improves corrosion resistance, especially in tough environments, such as marine or outdoor settings.

- Cobalt enhances the heat resistance and strength of certain stainless steel alloys, which is important for high-performance machinery or medical equipment.

So, knowing what’s in your stainless steel can help you understand its durability, what it’s best used for, and how long it will last under specific conditions. Whether you're looking for stainless steel discoloration prevention, strength for t sections, or simply wondering how to drill through stainless steel without ruining your tools, these ingredients play a role in the outcome.

Common Stainless Steel Issues: How to Handle Them

Now, let’s talk about some common issues you might face when working with stainless steel. One of the things people notice over time is chemical stain on stainless steel. Even though stainless steel is resistant to rust, it can still get stained by harsh chemicals or cleaners. If you've ever used strong cleaning products on your stainless steel kitchen appliances, you might have noticed some discoloration or streaks.

Stainless steel discoloration is often caused by heat, chemical reactions, or prolonged exposure to moisture. The good news is that most discoloration can be cleaned off using the right cleaning methods. If you see chemical stain on stainless steel, it’s best to use a non-abrasive cleaner designed specifically for stainless steel. Avoid using harsh chemicals or steel wool, as they can damage the surface and make the stain worse.

If you’re curious about how to clean or repair stainless steel discoloration, there are various cleaning products available that can restore its shine and appearance without causing further damage.

How to Drill Through Stainless Steel

Drilling through stainless steel can be challenging because of how tough the material is. Whether you’re trying to add holes to t sections for construction or making adjustments to stainless steel parts, knowing how to drill through stainless steel properly is essential. First, you’ll want to use the right drill bit. High-speed steel (HSS) drill bits work well for most types of stainless steel, but for thicker materials, you may want to use cobalt drill bits, as these are stronger and can handle the hardness of stainless steel better.

When drilling, keep the drill bit cool by applying cutting fluid or oil to the surface. This reduces friction, helps extend the life of the drill bit, and minimizes the risk of damaging the steel.

Can Stainless Steel Rust or Discolor?

It’s important to note that even though stainless steel is highly resistant to rust, it’s not completely immune. Stainless steel discoloration can happen, especially when exposed to certain conditions like high heat, harsh chemicals, or saltwater. If you’re working with stainless steel in a marine environment or around saltwater, it might be more prone to discoloration or minor rusting over time.

The best way to prevent rust and discoloration is to keep the stainless steel clean and avoid prolonged exposure to harsh chemicals. Regular cleaning and maintenance will keep your stainless steel in good condition for years to come.

Conclusion

To wrap it up, nickel and cobalt are both important components in the makeup of stainless steel, but they serve different purposes. Nickel is most commonly used to enhance corrosion resistance, durability, and appearance, while cobalt is used in specific high-performance alloys to improve heat resistance and strength.

So, next time you use stainless steel for a project, whether it’s for construction, cooking, or medical tools, you can rest assured knowing that these elements play a big role in making stainless steel what it is—strong, durable, and resistant to the elements.

Remember, knowing a little about the metals in your stainless steel can help you choose the right product for the right job, avoid chemical stain on stainless steel, and prevent discoloration. Happy working with stainless steel!