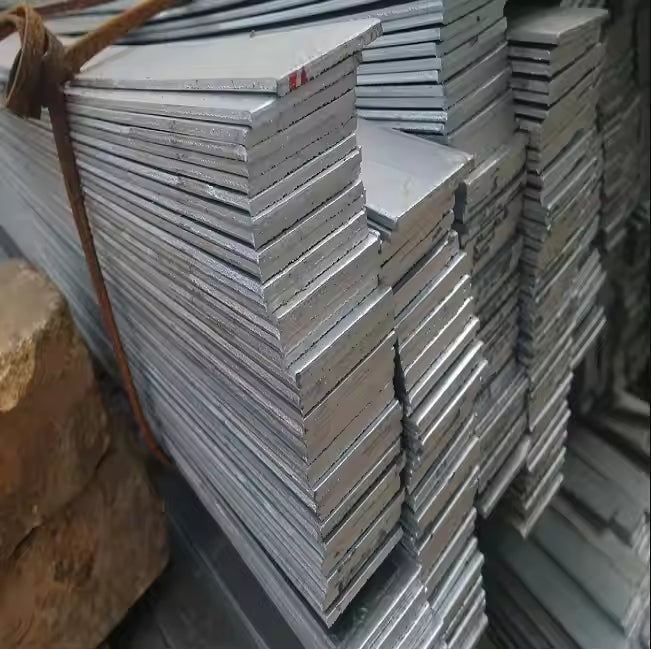

304L Stainless Steel Flat Bar

304L Stainless Steel Flat Bar

Contact form

The 304L stainless steel flat bar represents the most widely used austenitic stainless steel grade, featuring an impressive composition of 18% chromium and 8% nickel, with a maximum carbon content of 0.030%. This versatile stainless steel flat bar, often referred to as 18-8, combines exceptional corrosion resistance with mechanical properties comparable to structural steels.

Key Features and Benefits

The 304L stainless steel flat bar offers several advantages:

Corrosion Resistance:

- Superior resistance to various corrosive environments

- Excellent protection against intergranular corrosion

- Enhanced resistance in welded constructions

Processing Characteristics:

- Non-magnetic in annealed condition

- Not hardenable by heat treatment

- Strength improvable through cold working

- Excellent weldability due to low carbon content

- Ideal for welded constructions up to 800°F (427°C)

Applications and Industries

This versatile stainless steel flat bar finds extensive use in:

Food and Beverage:

- Food processing equipment

- Kitchen benches and troughs

- Sanitary installations

Industrial Applications:

- Chemical containers

- Heat exchangers

- Water filtration screens

- Dying industry equipment

Specialized Sectors:

- Automotive components

- Aerospace equipment

- Architectural molding

Technical Advantages

The 304L variant of stainless steel flat bar offers specific benefits over standard 304:

- Lower carbon content (0.030% max)

- Prevention of harmful precipitation between 800°F to 1500°F

- Superior performance in welded heavy sections

- Enhanced cleanliness and sanitation properties

- Improved weldability without post-weld heat treatment

These characteristics make 304L stainless steel flat bar the preferred choice for applications requiring both strength and corrosion resistance, particularly in environments where welding is necessary and post-weld heat treatment isn't practical.

Share