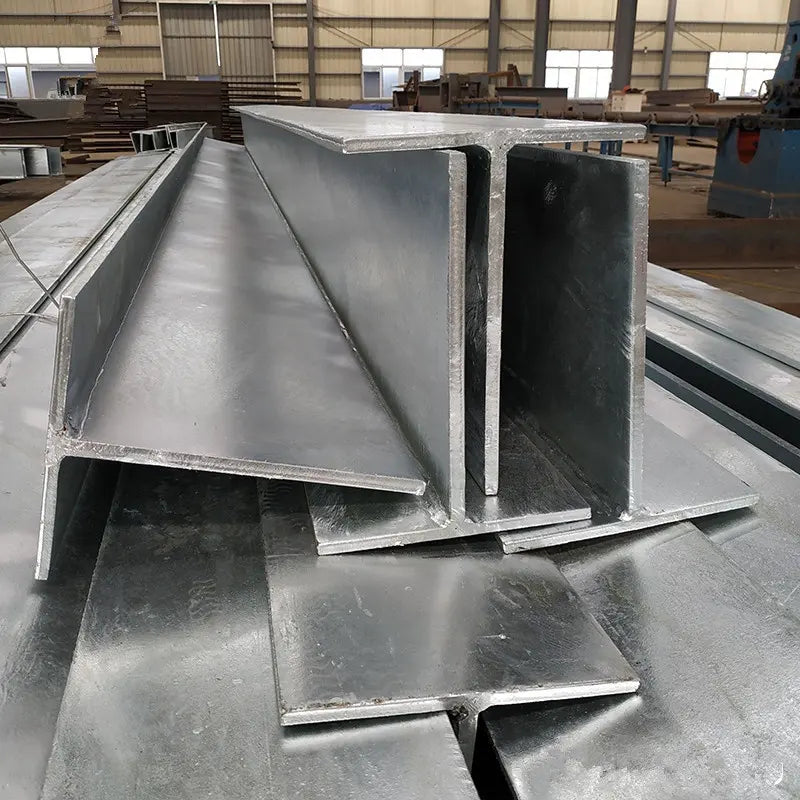

316L Stainless Steel T Section

316L Stainless Steel T Section

Contact form

Technical Specifications and Properties of Stainless Steel T Section Products

Standard compliance: ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311, DIN 1654-5, DIN 17440, KS D3706, and GB/T 1220 Available Processing:

- Surface Finishes: Bright, Polishing, Pickled, Peeled, Black, Grinding, Mill, Mirror, Hairline

- Manufacturing Methods: Cold Drawn, Hot Rolled, Forged

- Tolerances: H9, H11, H13, K9, K11, K13 or as customized

When comparing Stainless Steel T Section options, both 316Ti and 316L grades offer exceptional performance characteristics. The 316Ti variant includes titanium for enhanced intergranular corrosion resistance at temperatures between 425 and 815 degrees Celsius.

Applications and Performance Features

Ganpat Industrial Corporation specializes in premium Stainless Steel T Section products, including both 316L Stainless Steel T Section and 316Ti variants. These high-alloy austenitic stainless steel products are engineered for demanding environments, particularly in phosphoric acid processing applications.

Key advantages include:

- Superior corrosion resistance in aggressive environments

- Enhanced performance in high-temperature applications

- Excellent resistance to polythionic acid attack during operational cycles

- Effective protection against naphthenic acid corrosion in oil refineries

- Outstanding durability across various atmospheric conditions

The molybdenum and nickel content in our Stainless Steel T Section products provides exceptional protection against various forms of corrosion. While the 316L Stainless Steel T Section offers excellent general corrosion resistance, the 316Ti variant provides additional benefits at elevated temperatures due to its titanium stabilization, making it particularly suitable for high-temperature applications with prolonged exposure.

Both grades maintain superior performance characteristics in demanding industrial applications, with the specific choice depending on operating temperature requirements and environmental conditions.

Share