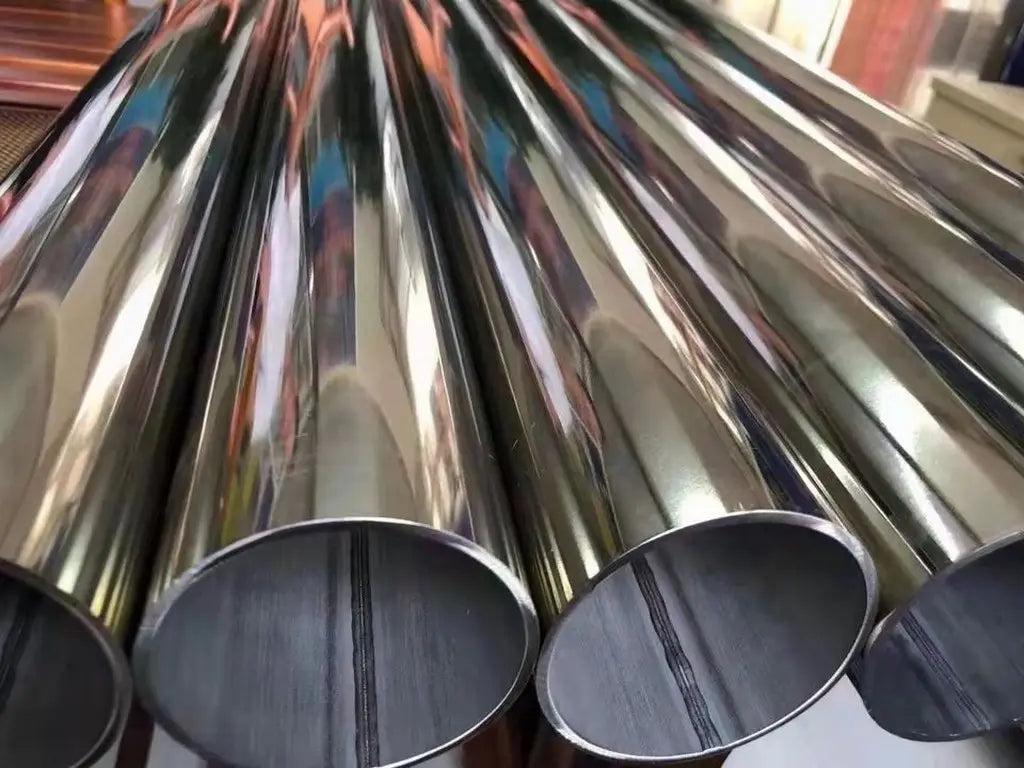

316L stainless steel welded pipe

316L stainless steel welded pipe

Contact form

Understanding 316L Stainless Steel Welded Pipe Specifications

The 316L stainless steel welded pipe is crafted from austenitic stainless steel, distinguished by its composition of chromium, nickel, and molybdenum with reduced carbon content compared to standard 316 grade. This lower carbon content makes it particularly suitable for welding applications. Its exceptional resistance to chloride ion corrosion makes it ideal for aqueous environments, thanks to its molybdenum content.

Applications and Dimensional Range of Stainless Steel Welded Pipe

In the stainless steel welded pipe family, 316L grade offers various manufacturing methods including welded, seamless, and fabricated options. The electric fusion welded pipes are available in impressive sizes ranging from 6 inches to 100 inches, while standard welded versions span from ½ inches to 24 inches. These 316L stainless steel welded pipes demonstrate remarkable performance characteristics:

- Longitudinal yield strength: 240 N/mm²

- Transverse yield strength: 270 N/mm²

- Tensile strength: 530-680 N/mm²

- Extension capability: 40%

- Maximum operating temperature: 870 degrees Celsius

The ASTM A312 TP316L specification demands a minimum yield strength of 205MPa and minimum tensile strength of 515MPa. These stainless steel welded pipes are manufactured through either end-to-end sheet welding or spiral strip welding processes, though they may have slightly higher surface roughness compared to seamless variants.

For industrial, commercial, and corrosive service applications, the SS UNS S31603 (316L) welded pipes provide reliable performance under high pressure and elevated temperature conditions. The MT Industrial Division ensures all 316L stainless steel welded pipe products meet strict quality parameters and comply with the highest fluid handling certifications.

Share