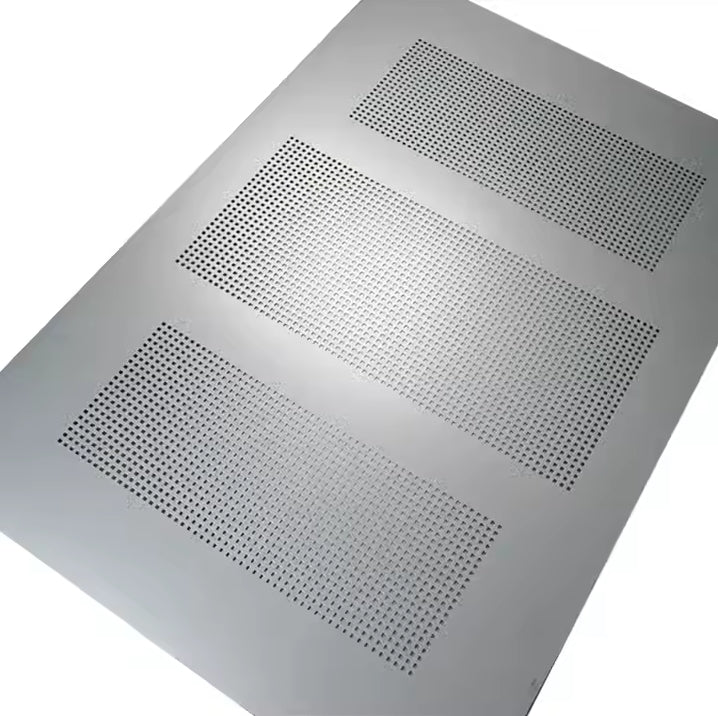

321 Perforated Stainless Steel Sheet

321 Perforated Stainless Steel Sheet

Contact form

Understanding 321 Perforated Stainless Steel Sheet Composition

The 321 Perforated Stainless Steel Sheet represents a significant advancement in stabilized stainless steel technology. This specialized alloy (S32100) is engineered with titanium stabilization, which provides exceptional resistance to intergranular corrosion, particularly when exposed to temperatures ranging from 800°F to 1500°F (427°C to 816°C). The addition of titanium effectively prevents chromium carbide formation, ensuring the material maintains its structural integrity under demanding conditions.

Applications and Advantages of 321 Stainless Steel Perforated Sheet

The Stainless Steel Perforated Sheet in grade 321 finds extensive applications across various industries due to its remarkable properties:

Key advantages include:

- Superior corrosion resistance

- Excellent tensile strength

- Outstanding welding characteristics

- Versatile fabrication options

Industry applications for 321 Perforated Stainless Steel Sheet include:

- Chemical processing plants

- Cement manufacturing facilities

- Food processing equipment

- Agricultural machinery

- Automotive components

It's worth noting that 321H grade Perforated Sheets feature a modified carbon content compared to standard 321 grade, offering specialized performance characteristics for high-temperature applications. The UNS S32109 Perforated Sheets maintain exceptional shape stability and can be welded using various techniques, making them highly versatile for industrial applications.

Our commitment to quality ensures that all 321 Perforated Stainless Steel Sheet products meet rigorous industry standards while offering competitive pricing and reliable delivery schedules. Whether your application requires standard or custom perforation patterns, our sheets deliver consistent performance and durability.

Share