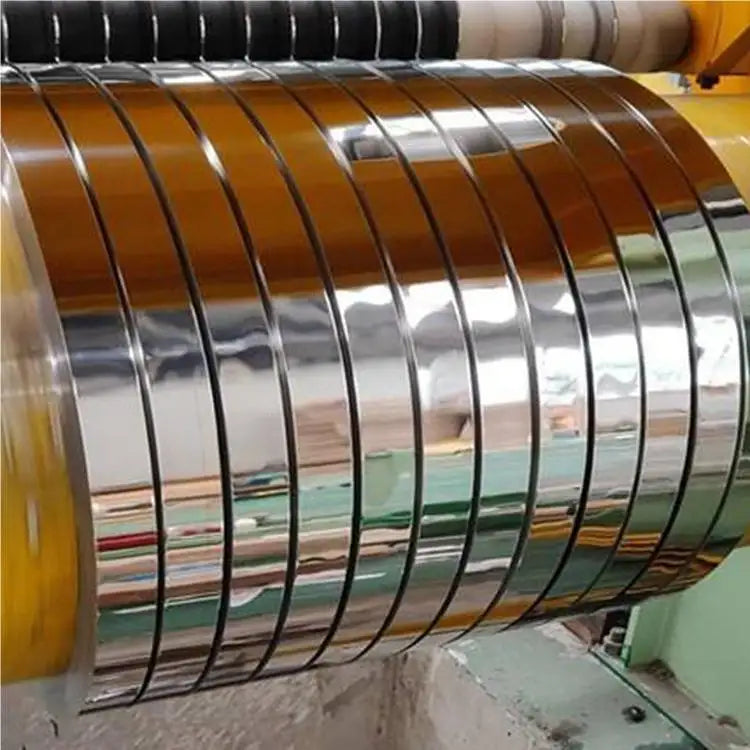

321 Stainless Steel Strip

321 Stainless Steel Strip

Contact form

Understanding 321 Stainless Steel Strip Properties

321 stainless steel strip represents a significant advancement in austenitic steel technology, featuring titanium stabilization that sets it apart from conventional alternatives. This specialized stainless steel strip (UNS S32100) maintains its structural integrity at temperatures up to 900°C, offering exceptional resistance to intergranular corrosion after heating. As a modified version of type 304, this premium stainless steel strip delivers outstanding performance in applications requiring sustained or intermittent exposure to temperatures between 800-1500°F (427-816°C).

Applications and Industrial Uses of 321 Stainless Steel Strip

The versatility of 321 stainless steel strip makes it ideal for various demanding industries:

- Aerospace components

- Oil & Gas equipment

- Chemical Processing facilities

- Food Processing systems

- Waste Treatment plants

Technical Specifications and Composition

The superior performance of 321 stainless steel strip is achieved through its carefully controlled composition:

- Chromium: 17.0 – 19.0%

- Nickel: 9.0 – 12.0%

- Titanium: 5*(C+N) – 0.70%

- Carbon: 0.08% max

- Iron: Balance

Physical Properties and Performance Characteristics

This premium stainless steel strip offers exceptional physical properties:

- Density: 0.290 lb/in³ (8.09 g/cm³)

- Modulus of Elasticity: 28.0 x 10³ ksi (193 GPa) at 70°F

- Superior oxidation resistance

- Excellent creep strength compared to other 300 series

- Enhanced intergranular corrosion resistance

- Easily fabricated and welded using conventional methods

The 321 stainless steel strip meets rigorous industry standards, including AMS 5510 and ASTM A240, ensuring consistent quality and reliability across all applications.

Share