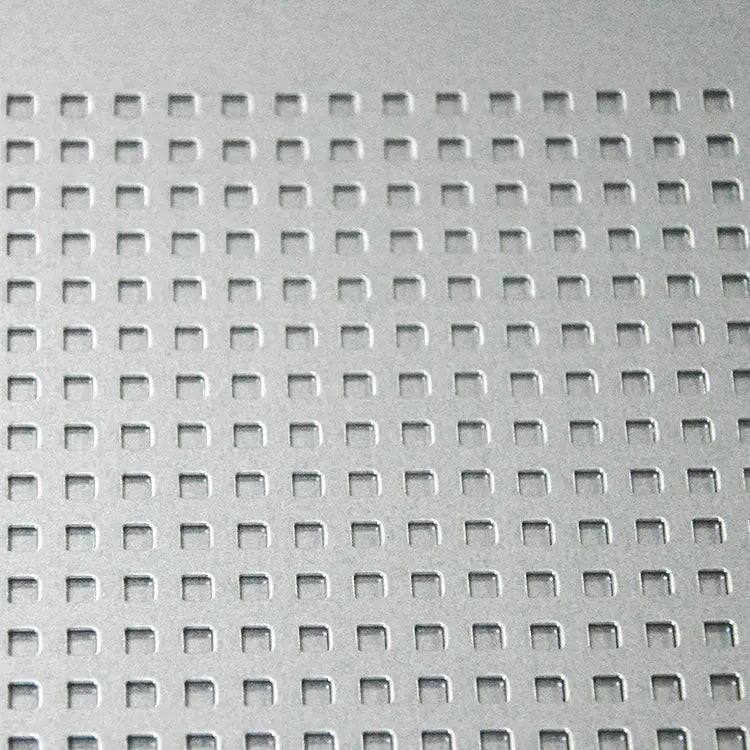

347 Perforated Stainless Steel Sheet

347 Perforated Stainless Steel Sheet

Contact form

347 Perforated Stainless Steel is a specialized columbium/tantalum stabilized austenitic chromium-nickel stainless steel. This high-performance material stands out due to its unique composition, where columbium and tantalum are added to prevent chromium carbide formation. These elements form carbides within the grains rather than at grain boundaries, enhancing the overall material stability.

The Stainless Steel Perforated Sheet in grade 347 demonstrates exceptional performance in various chemical environments, including:

- Nitric solutions at moderate temperatures

- Diluted organic acids

- High-temperature phosphoric acid (up to 10% concentration)

- Chloride or fluoride-free caustic solutions at low temperatures

Applications and Performance Characteristics of 347 Perforated Stainless Steel Sheet

This versatile 347 Perforated Stainless Steel Sheet excels in demanding applications, particularly:

- Temperature ranges between 800°F (427°C) and 1650°F (899°C)

- Welding operations where post-weld annealing isn't possible

- Hydrocarbon processing where polythionic acid stress corrosion resistance is crucial

Key features of these sheets include:

- Enhanced carbon content for improved strength

- Superior creep resistance

- Excellent performance at temperatures above 537°C

- Compatibility with standard shop welding practices

- Dual certification capability (347/347H)

The ASTM A240 UNS S34700 specification ensures consistent quality across cold-rolled sheets, making them ideal for industrial applications requiring both durability and precision perforation. While these sheets cannot be hardened through heat treatment alone, they respond well to cold working processes, offering flexibility in fabrication methods.

Share