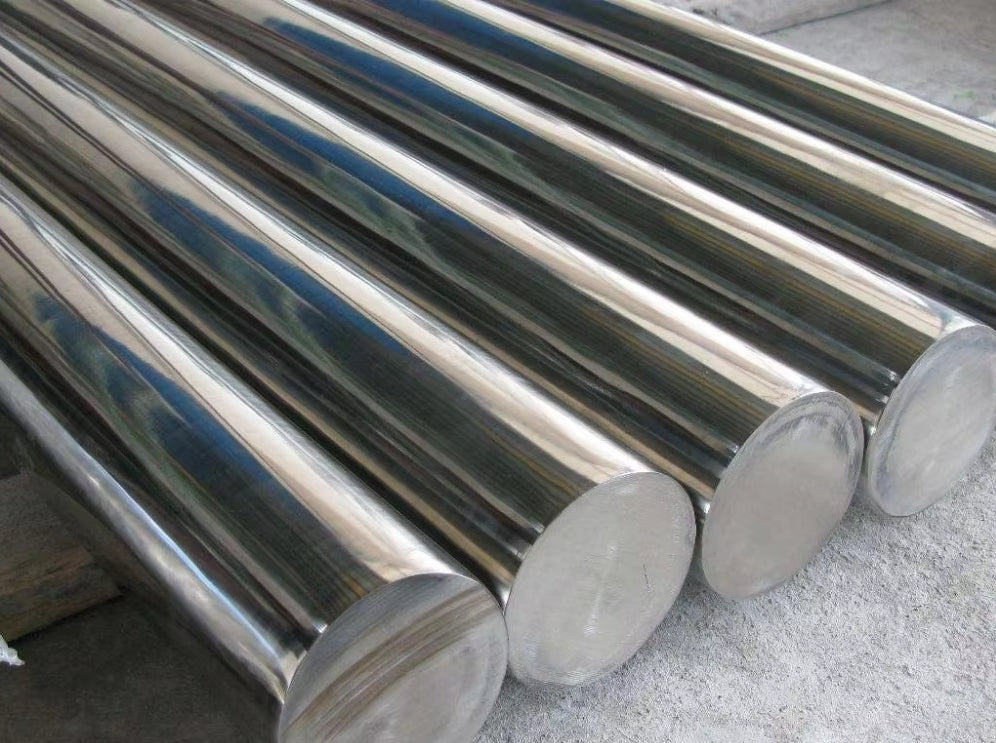

431 Stainless Steel Round Bar

431 Stainless Steel Round Bar

Contact form

Overview of 431 Stainless Steel

431 stainless steel is a martensitic stainless steel that is AOD melted, known for its excellent corrosion resistance among 400 series stainless steels. This alloy can be heat treated to achieve high strength levels, making it a preferred choice in the aerospace industry for fittings and boltings that require high yield strength. Its corrosion resistance also makes it suitable for marine applications.

Key Features

431 stainless steel is designed to offer improved corrosion resistance and toughness compared to other 400 series grades, especially in quench-hardenable forms. Its properties make it well-suited for marine environments and aerospace applications, including aircraft fasteners and fittings. This alloy exhibits great impact strength at high hardness levels.

Among all martensitic grades, 431 stainless steel has the best corrosion resistance, second only to age-hardenable martensitic grades. Its applications include bomb racks, bolts, pump shafts, valve stems, and aircraft fasteners. The 431 stainless steel round bar is particularly popular for its versatility and performance in demanding environments.

Mechanical Properties

431 is a high chromium-low nickel martensitic stainless steel with high hardenability, typically supplied in a hardened and tempered condition. It has a tensile strength range of 850 to 1000 MPa (condition T) and a Brinell hardness range of 248 to 302. This grade exhibits excellent corrosion resistance in various atmospheric environments, as well as resistance to mild marine and industrial atmospheres, organic materials, nitric acid, and petroleum products.

Due to its excellent hardenability, 431 can be through-hardened up to Rc44, depending on carbon content and section size. Smaller sections can be air-cooled, while larger sections should be oil-quenched for maximum hardness. Pre-hardened and tempered 431 can also respond well to nitriding, achieving a surface hardness over Rc65, although this process may reduce corrosion resistance and is generally not recommended unless critical.

Considerations

- Low Temperature Properties: 431 is not recommended for use at sub-zero temperatures due to a significant drop in impact properties, consistent with most non-austenitic steels.

- Cold and Hot Bending: Cold bending in the hardened condition is extremely difficult due to high yield strength, and hot bending is not recommended as it affects mechanical properties.

- Corrosion Resistance: 431 stainless steel exhibits the highest corrosion resistance among martensitic stainless steels, comparable to certain austenitic grades like 301 and 302, especially in its hardened and tempered condition.

To ensure optimal corrosion resistance, the surfaces of 431 stainless steel round bars must be free of scale and contaminants, allowing oxygen to circulate freely to maintain a protective chrome oxide film.

Forging Guidelines

To forge 431 stainless steel, heat it uniformly to 1150°C - 1200°C, holding until the temperature is consistent throughout. Forging should commence immediately without soaking, and care should be taken not to overheat, as this can lead to a loss of toughness and ductility. Finished forgings should be cooled slowly in dry lime or ashes to room temperature, followed by immediate sub-critical annealing.

Share