631 Stainless Steel U Channels

631 Stainless Steel U Channels

Contact form

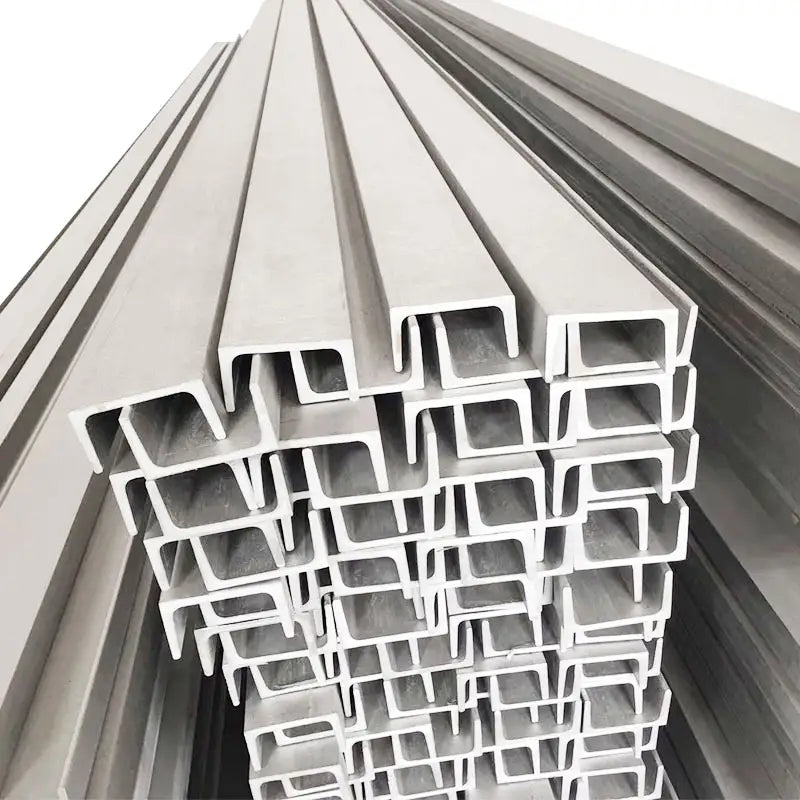

Our 631 (1.4568) Stainless Steel U Channels represent the highest grade of precipitation-hardened stainless steel, featuring superior chromium (17%) and nickel (7%) content compared to other PH grades. These premium Stainless Steel Channel products deliver exceptional strength properties, superior hardness, and outstanding elasticity, making our Stainless Steel U Channel solutions ideal for demanding applications requiring excellent corrosion resistance and high-temperature stability.

Heat Treatment Specifications for 631 Stainless Steel Channel Products

Our channels are available in multiple treatment conditions:

- Condition A: Saturation at 1065°C

- Condition TH1050:

- Saturation at 760°C (1400°F) for 1.5 hours

- Cooling to 15°C (55°F) for 0.5 hours

- Aging at 566°C (1050°F) for 1.5 hours

- Condition RH950:

- Saturation at 954°C (1750°F) for 10 minutes

- Cooling to -73°C (-100°F) for 1.5 hours

- Aging at 510°C (950°F) for 1 hour

- Condition C: Post cold rolling

- Condition CH900: Cold rolled with aging at 482°C (900°F)

Manufacturing and Processing Capabilities

Welding Characteristics

Our 631 Stainless Steel U Channels can be processed using standard arc and resistance methods. We recommend inert gas shielding during fusion welding to protect aluminum content.

Aging Process

The precipitation hardening process includes:

- Solution annealing at 1177°C (2150°F) for 4 hours

- Secondary annealing at 1079°C (1975°F) for 4 hours

- Tertiary treatment at 843°C (1550°F) for 24 hours

- Final aging at 760°C (1400°F) for 16 hours

Machining Guidelines

Our Stainless Steel U Channel products offer:

- 75% machinability rating compared to B1112

- Optimal results with slow speeds and constant feeds

- Special considerations for chip breaking during machining

- Clean, scale-free surfaces for superior performance

Each 631 Stainless Steel U Channel is carefully processed to ensure optimal mechanical properties and performance characteristics for demanding industrial applications.

Share